Kranzle UK frequently asked questions and help section:

- General Help & Advice

-

Round Cleaner Guidance

-

• Round Cleaner UFO models

Best results supply with 10-11 ltrs/min and 120 Bar pressure (180 Bar max.)

• Round Cleaner UFO stainless steel models

Best results supply with 10-14 ltrs/min and 130 Bar pressure (210 Bar max.)

Note :

(K 1050) Round Cleaner UFO Light versions with smaller nozzles for use with the HD 7/122, HD 7/122 TS and older Silent 122 series machines.

Please specify this when ordering as an adapter between the trigger gun and the accessory is required, Order No. 12436 to fit QR trigger gun or 12435 to fit M22 trigger gun

• Round Cleaner INOX 300 models

Best results supply with 10-14 ltrs/min and 130 Bar pressure (250 Bar max.)

• Round Cleaner INOX 410 models

Best results supply with 11-15 ltrs/min and 140 Bar pressure (250 Bar max.)

• Round Cleaner INOX 520 models

Best results use over 14 ltrs/min and 180 Bar pressure (250 Bar max.)

Lance styles and advice

Almost all lances are available with different sized nozzles, please check your operators manual or take a look at our nozzle chart for working this out

> Vario Duo lances

Adjustable spray pattern lance

> Vario lances

Adjustable spray pattern lance, also with option to operate low pressure chemical injector, or low rinse

> Lances with Chem Reg.

Fixed knife-jet spray pattern lance with option to operate low pressure chemical injector, or low rinse

> Fixed Jet Lances

Fixed knife-jet spray pattern lance

> AJN Lances

Fixed knife-jet spray pattern lance with option to operate low pressure chemical injector, or low rinse

> DirtKiller and TurboKiller Lances

The floating, spinning pencil jet nozzle offers a very concentrated jet; the spinning action also creates a more powerful ripping force which as the nozzle rotates around its central point allows for coverage of a greater area. Maximum impact pressure over a larger area than previously possible. Built to last with solid brass ends, protected by a plastic or rubber casing. Inside is ceramic, while using ceramic is not cheap, it is extremely hard wearing and is very unlikely to ever wear-out.

Dirtkillers work best with outputs up tp 15 ltrs/min.

Turbokillers work best with outputs above and over 15 ltrs/min.

Do not think that because the Turbo Lances cost more that they are more powerful - they are not. They are simply bigger and designed for machines pumping out higher volumes of water

Nozzle chart guide

Almost all appliances are available with different sized nozzles and having the right one is very important. Please check your operators manual or take a look at our nozzle chart for help identifying which size you need, the spray angle is not so important as the size : though offers you a wider choice.

Trigger gun options

Most Kranzle high-pressure cleaners are supplied with:

The Kranzle Stalrlet 4 mid length trigger gun.

The Kranzle Starlet 3 short gun is our heavier duty trigger gun and is supplied as standard with our larger series and 400 volt machines.View our full range of trigger guns available here Have a fault with your existing gun?

The most common problem is a leak from where you can swap over your lance attachment or accessories to the trigger gun.

The seal here is not formed by the thread but by the green viton o-ring.

We advise against replacing the o-ring with a black nitril o-ring as these are usually thinner, less resistant to chemicals and detergents and don't last as long as the genuine o-ring.

Many Kranzle trigger guns can be serviced, they are easy to take apart by removing a handfull of screws and exploded parts diagrams are both in your operator manual and also found on our website.

Some spare parts and repair kits are available if needed, it may only require adjusment of the trigger mechanism.

If the trigger is not opening or not shutting off properly, you may want to try adjusting the locking nuts first:

The M2000 gun;

> Loosening the nuts off should allow the torpedo to travel towards it's seat better in instances where the gun is not shutting off.

> Tightening the nuts up should be tried when the gun is not opening up.

Hose & Electric extensions

Correct supply and set-up can be vital!

Please view the "Setting up" section of our website where important information is offered with regards to using:

Low-pressure hose

High-pressure hose

Power supply

view set-up details here

Machine / Series suitability advice

See what recommendations we would offer based on your usage!

Please use this guide to direct you towards the best series of Kranzle products for your demands!

A guide to help select your " proper solution " here

Do I have to register for warranty

As per the operating manual supplied with all new machines:

“The product is to be operated in conformity with this operating manual.

The operating manual is deemed to be part of the warranty provisions.”

On the same page, it also references that: ”Where warranty claims apply, please contact your supplier, presenting the machinery/accessories together with your purchase receipt”.

So in essence, as long as you keep the receipt and the operating manual & spare parts list, there’s nothing to do but enjoy using your new Kranzle!

If you do ever run in to any problems, check the operators manual for any common simple 'DIY fixes' available or contact your supplier who'll be able and happy to help.

Warranty on our industrial equipment is 12 months from the date of purchase, however, there is an option to increase the warranty to 24 months providing the machine has been serviced by an approved servicing agent and a record of this in accordance with its amount of use during the initial 12 month warranty period, Kranzle UK will then provide parts warranty cover for a further 12 months. Warranty to a domestic user who uses a professional machine purely for home use is 24 months as standard.

- Trouble shooting help and suggestions

-

Operating chemical solutions

-

Kranzle foam bottle lances leave long lasting foam results

Low pressure chemical injectors operate on a Venturi system, physics kind of means they have to work. But, if you can't get your chemical to work..

Ensuring that the chemical hose with filter feed is fully submersed, then simply operate the chemcal feature on your lance:

> With the Vario lance, the adjustable spray pattern grip slides away from you to draw through the chemical.

> Lances with a chemical regulator, the end twists around to adjust the amount of chemical drawn in.If you are using long lengths of high pressure hose, the Venturi may not sufficiently operate but there are other suggestions or methods that may suit your exact requirements.

Usually only a problem with older machines, but it is possible for some more of the more gunky cleaning agents to dry around the spring inside the chemical in-let hose barb. The brass barb will unscrew using a spanner, try not to lose the barb, ball or spring and clean it up. If this continues to happen using your prefered cleaning agent, try drawing through a little water through the chemical hose before putting the machine away when you are done.

There's water in the pressure gauge

It is not water, it is glycerine

The gauge is about half full with glycerine so you may see a 'bubble'.

This all dampens the vibration of the needle allowing you to see what the pressure is, rather than just a blur.

Leakages

You may wish to first establish where the leak is: it may be a hose connection; it may be a loose oil sight glass..

Checking this before contacting a servicing agent may save you time and money.view servicing company details

Oil queries

All Kranzles come with the correct level of oil for you to use right away.

We always suggest that after the first 50 operating hours, taking care to ensure any waste oil is responsibly disposed of, drain the oil resevoir before re-filling. After the first oil change the oil should be changed depending on the use of the machine. Replacing the oil is then suggested after every aprox. 250 hours of use. To some that's every 3 months, but if you use the machine less, once a year or so would be a good idea.

It only takes a few parts per thousand of water to emulsify oil and make it appear 'milky'. Machines used near any sprayed water or in poorly ventilated enclosed spaces are typically going to build up condensation and temperature fluxuations also will effect the colour of the oil.

In cases of increased humidity or frequent fluctuations in temperature development of condensed water is possible.

If the oil turns grey or white, you must change it.

The only real way of getting all traces out of a water contaminated oil chamber is to strip down the machine and wipe clean all of the parts.

Tip: When re-filling after responsibly draining the old oil you may want to add just a little new oil and briefly turn the machine on for a second or two allowing movable transmission parts in contact with each other to move freeing otherwise trapped old oil, responsibly drain the oil again and repeat if required. Click here for guidance on this, with pictures.

Oil types and levels for appliances :

supplied in your operating manuals, alternatively contact your supplier

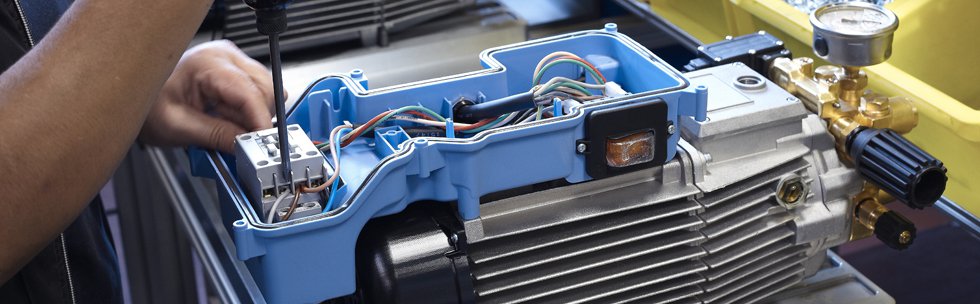

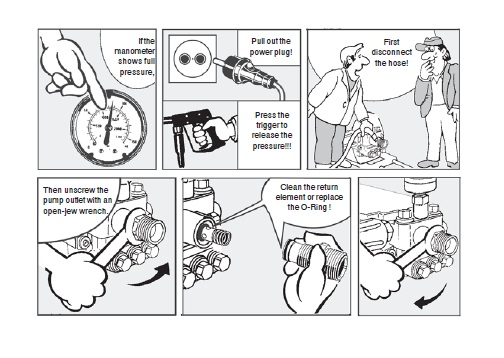

Do It Yourself - Small repairs

If you are experiencing an issue such as sudden low pressure or no waterflow at all then there may be a few simple steps to follow covered in the below to try first which could save you time and money:

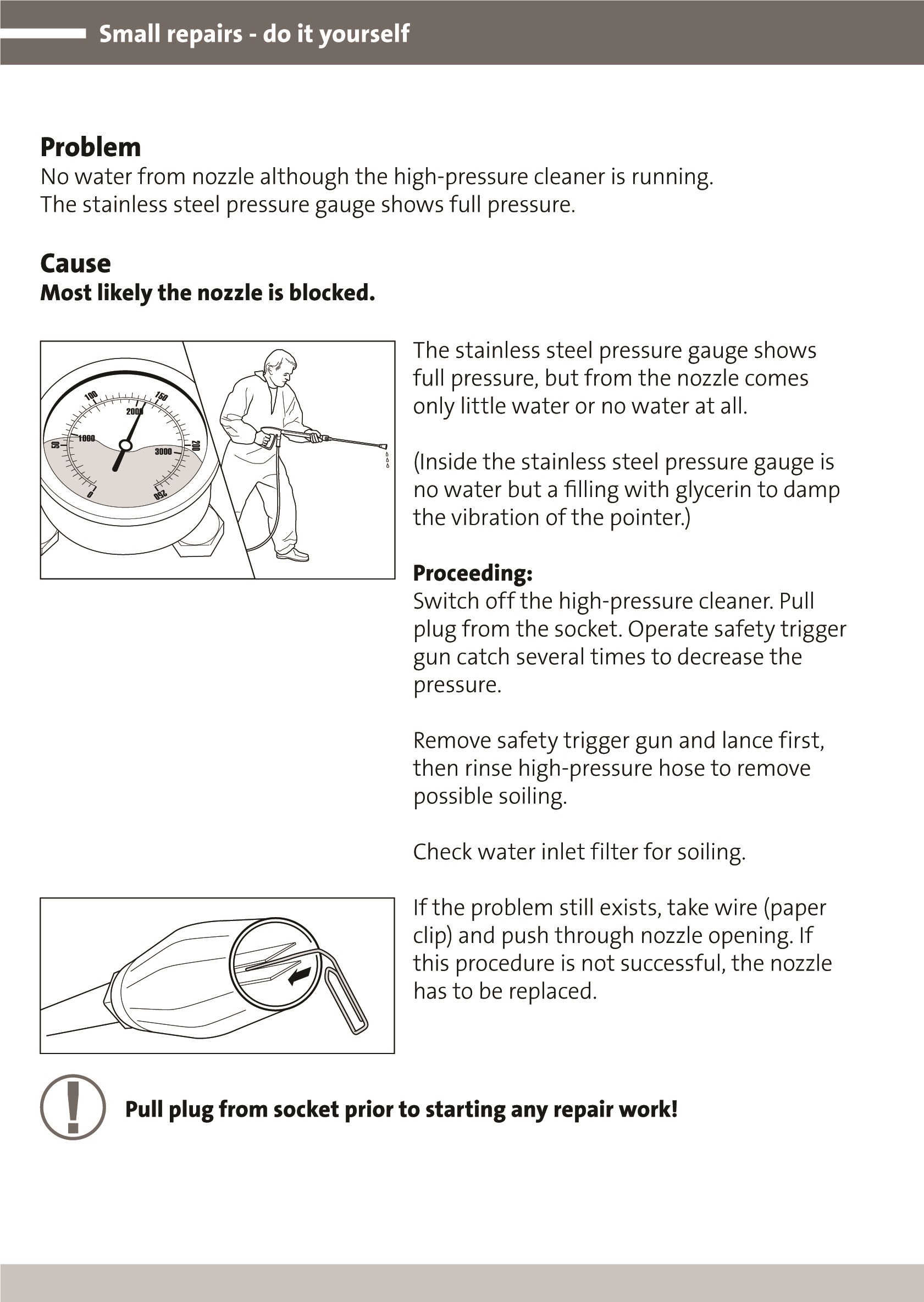

No water from nozzle although the high-pressure cleaner is running

The stainless steel pressure gauge shows full pressure..

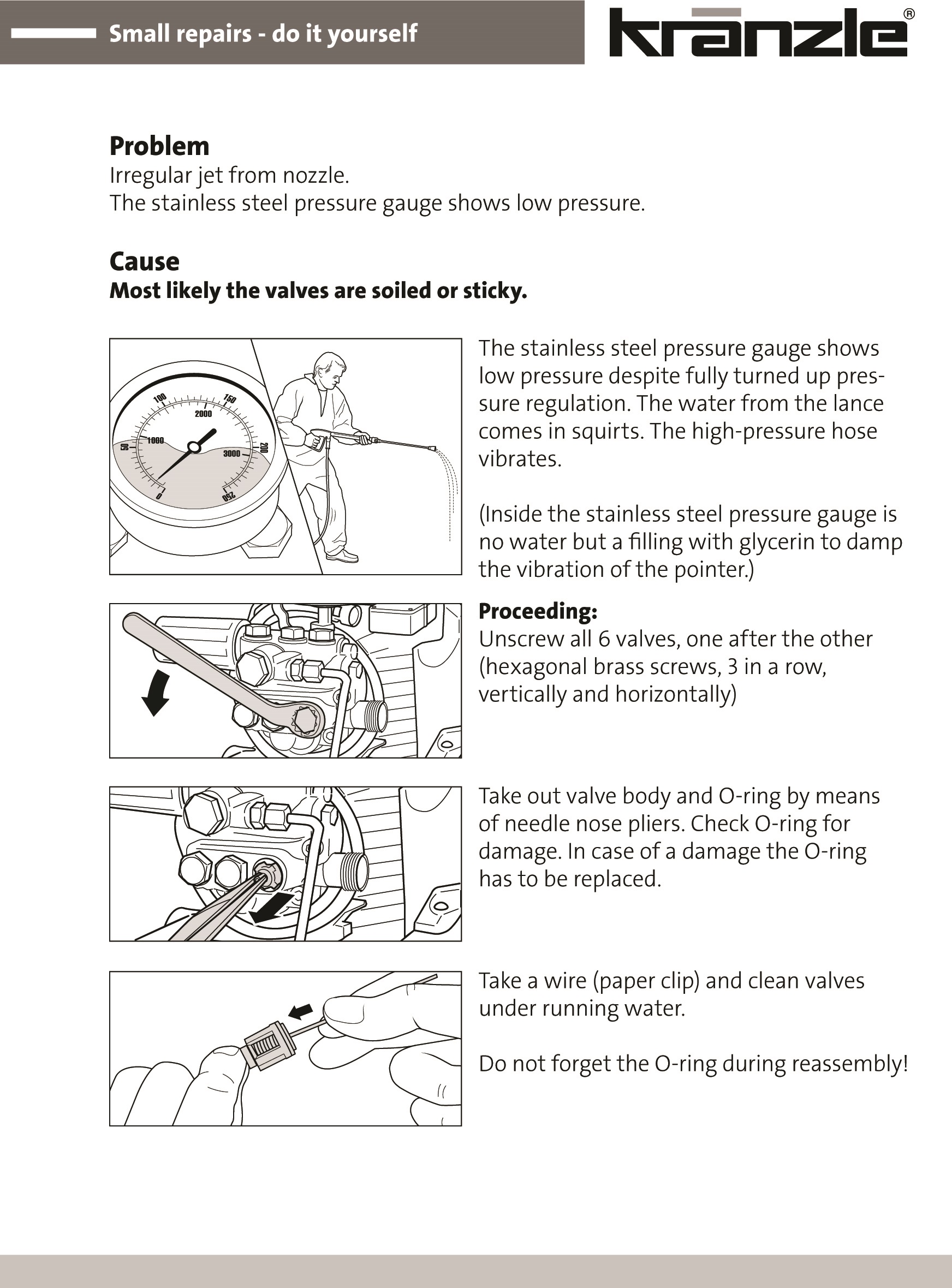

Irregular jet from nozzle.

The stainless steel pressure gauge shows low pressure...

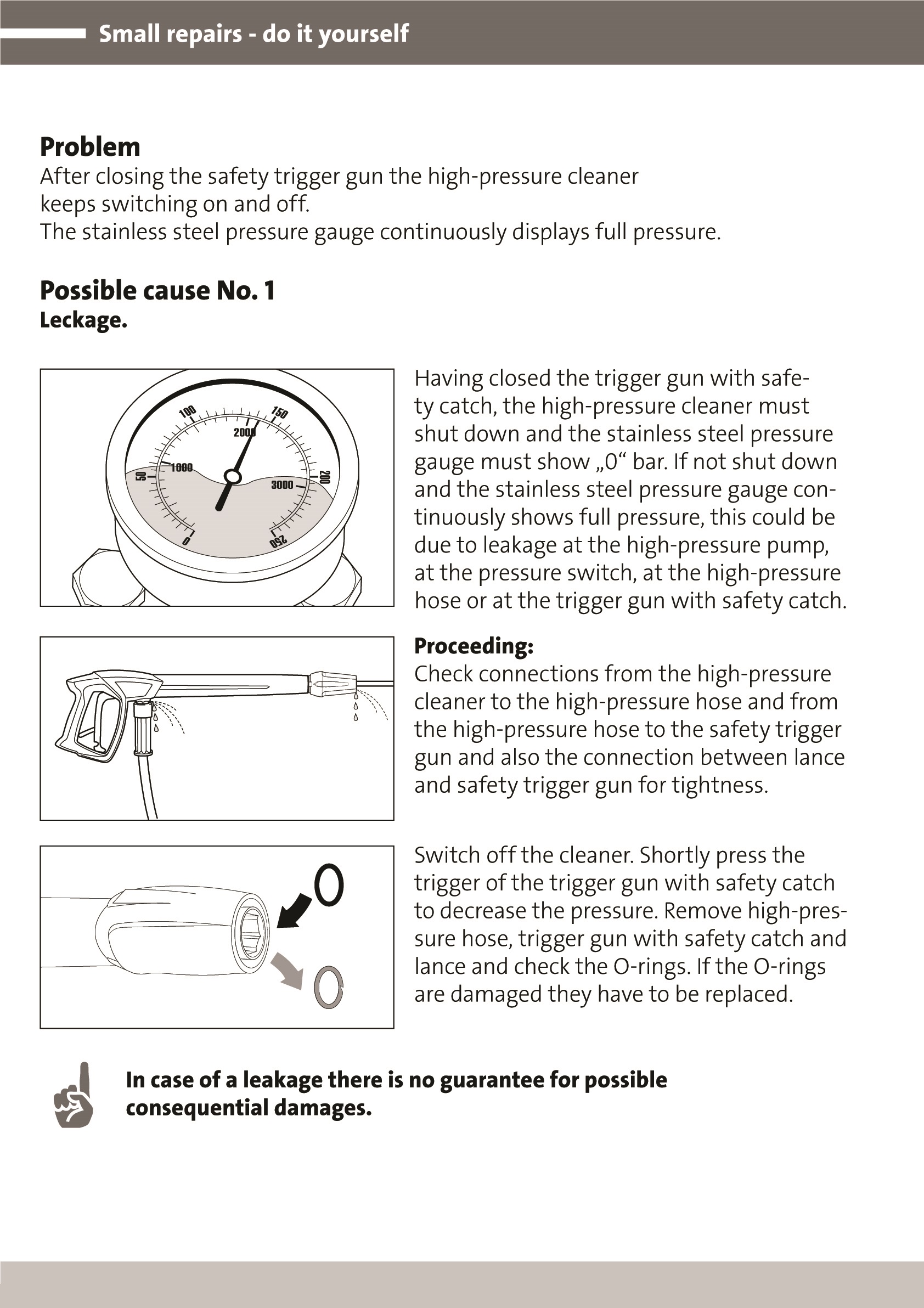

After releasing/closing the trigger gun the pressure gauge shows full pressure..

Possible cause No. 1 - Leakage

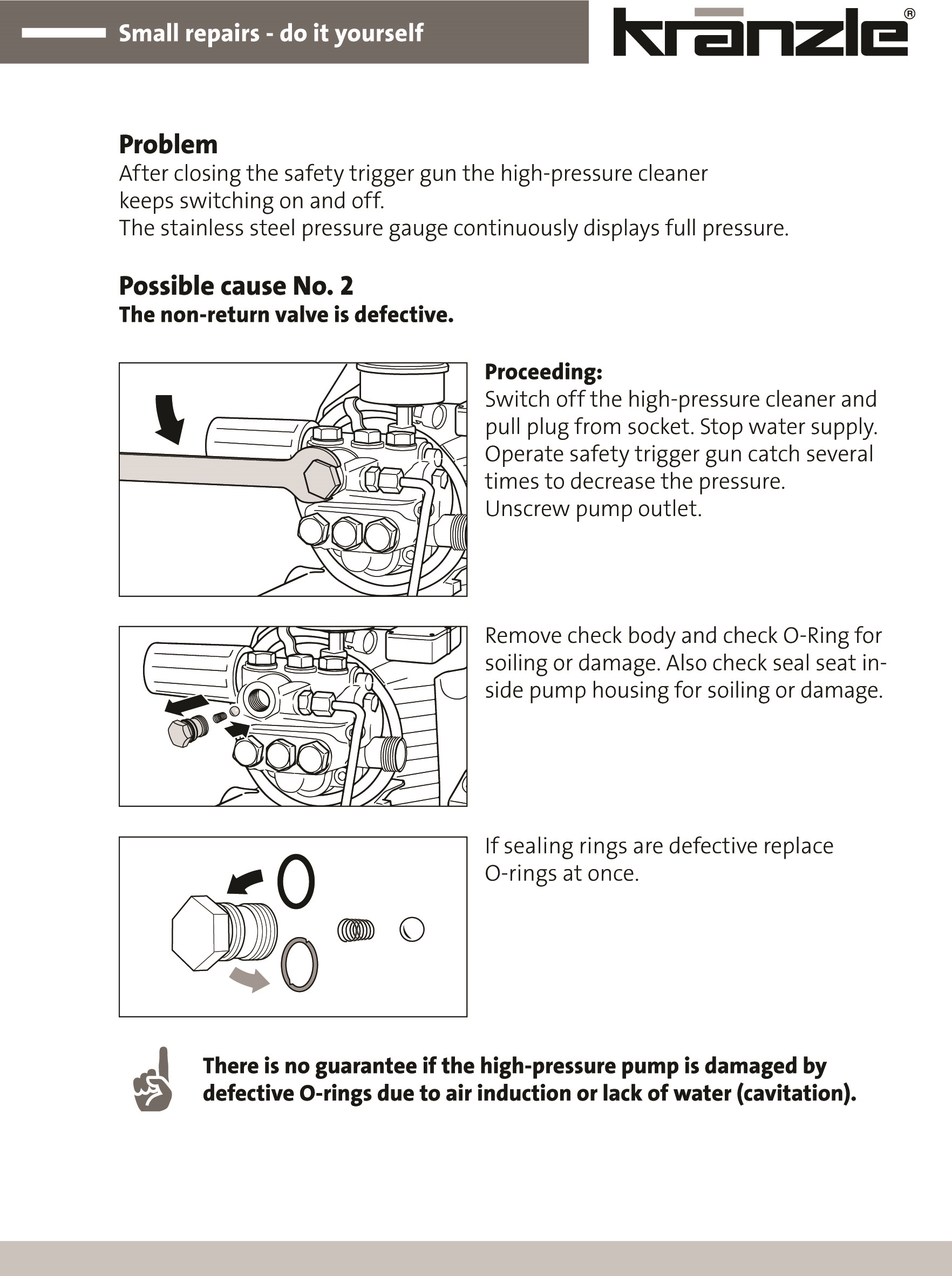

After releasing/closing the trigger gun the pressure gauge shows full pressure..

Possible cause No. 2 - The non-return system (NRS) may have debris blocking it or it has become defective

After releasing/closing the trigger gun the pressure gauge shows full pressure..

After releasing/closing the trigger gun the pressure gauge shows full pressure..

(Older backstorke body version)

Returns

Sometimes you want the experts to take a look!

Please use the correct form for any returns:

Click for Returns

Hide all